What’s the Difference Between Investment Casting and Sand Casting?

Sand casting and investment casting are methods of creating metal parts by pouring molten metal into three-dimensional molds. Although methods are thousands of years old, both have been refined over the years to minimize the amount of metal used and reduce any extensive machining and finishing required. But significant differences exist between these two methods of making metal parts. First let’s take a look at the basics behind each.

Sand-Casting Basics

Molten metal gets poured into the sand-based molds during sand casting.

In sand casting, molten metal, usually iron, steel, bronze, brass, aluminum, magnesium, and other non-ferrous alloys, is poured into a two-piece mold. The molds are created by compacting sand—most often mixed with clay as a bonding agent and moistened with water—around a pattern or model of the final product. The mold is split apart and the pattern removed. The two halves of the mold are put back together and the void is filled with molten metal. Once the metal cools sufficiently, the mold is opened, the sand removed, and the part taken out.

Several of the same parts can be cast at the same time, or a range of different parts can share a mold. Molds are destroyed in the process, but new ones are easy to make. The sand is often reclaimed and reused multiple times.

Investment-Casting Basics

Investment casting, also called lost-wax casting, makes parts from molten metal, usually stainless-steel alloys, brass, aluminum, and carbon steel. The first step in the process is to build a wax version of the final product. This can be done in one of three ways:

- Form a gelatin mold around a solid, 3D model of the final product.

- Create a metal mold of the final product, and then fill it with hot wax.

- Carve and machine a replica of the product out of wax.

To cast several parts at once, several wax patterns can be assembled into a tree with wax runners and sprues carefully connecting them. The “tree” is then repeatedly dipped in a ceramic slurry that hardens when it dries. After receiving several layers of ceramic that are allowed to harden, the tree and its patterns are heated to remove the wax. The wax in the sprues and gates also flows out of the tree and forms tubes and pipelines for molten metal to follow and completely fill the mold.

Molten metal is poured into the now-empty mold and left to solidify. The ceramic mold, the investment, is destroyed to remove the part(s).

Differences

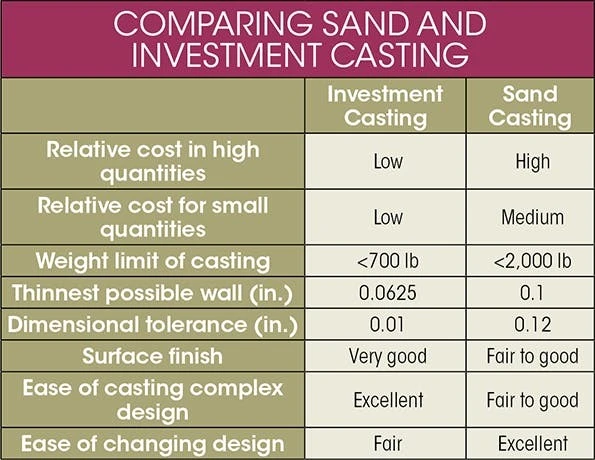

Due to the complexity and preparation needed, investment casting is often much more expensive than sand casting. But sand casting cannot always make the small, intricate parts possible with investment casting. And while investment castings can make parts weighing only fractions of an ounce, they are limited in terms of the size and weight of parts made with sand casting.

Another major difference between investment and sand casting is the surface finish of the final product. With sand casting, the mold has to be split apart to release the final product. As a result, finished parts have a seam left by the parting lines in the mold. And the sand, which is relatively rough, leaves an equally rough surface on cast parts. In many instances, the parting line and roughness are smoothed over in secondary machining processes, but this requires additional time and labor.

Investment casting, on the other hand, uses ceramic molds that are hard. Finished parts exhibit smooth surfaces and low tolerances, and can have thin walls. After removing the gates and sprues, the cast parts often don’t require any secondary processing.

Investment casting uses liquid slurry to form the molds, so cast parts can have almost any shape, giving engineers extraordinary freedom in their designs to add intricate features and complex shapes. Sand-cast parts usually have to be tapered (with draft angles) or shaped so that they come out of the compacted sand easily and with little friction. It’s also a challenge to sand-cast parts with internal voids or cavities. It requires cores properly shaped and inserted in the mold to form the part’s interior. Several cores may be needed, and it can be time-consuming to form and secure them within each mold.

One advantage of sand casting is that it is relatively simple to change the mold (by modifying the pattern or core boxes, often made of wood) to accommodate design changes. With investment casting, technicians may need to modify or replace the solid metal pattern, or make new molds for turning out wax versions, which can be a more complicated process.